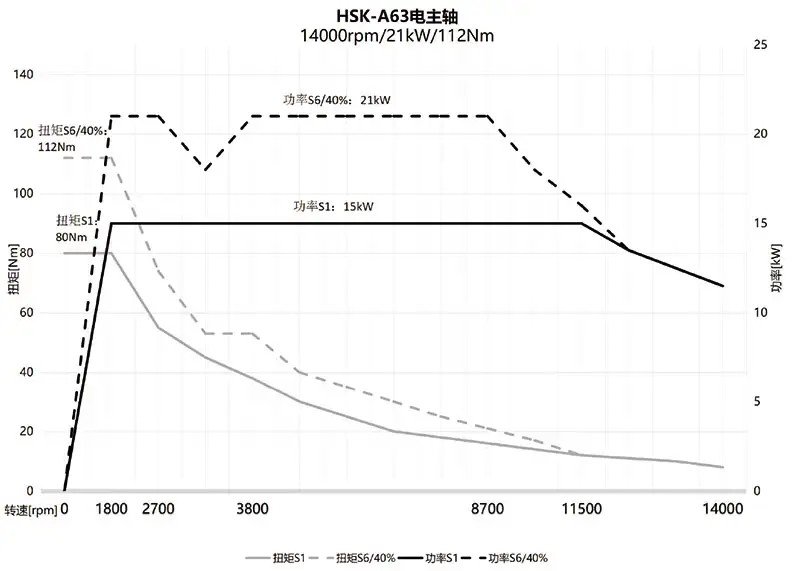

The vertical machining center adopts a high-rigidity structural design and a precision guiding system to ensure a stable and reliable machining process. The high-speed spindle system supports precision machining of multiple materials, suitable for efficient cutting of complex parts.